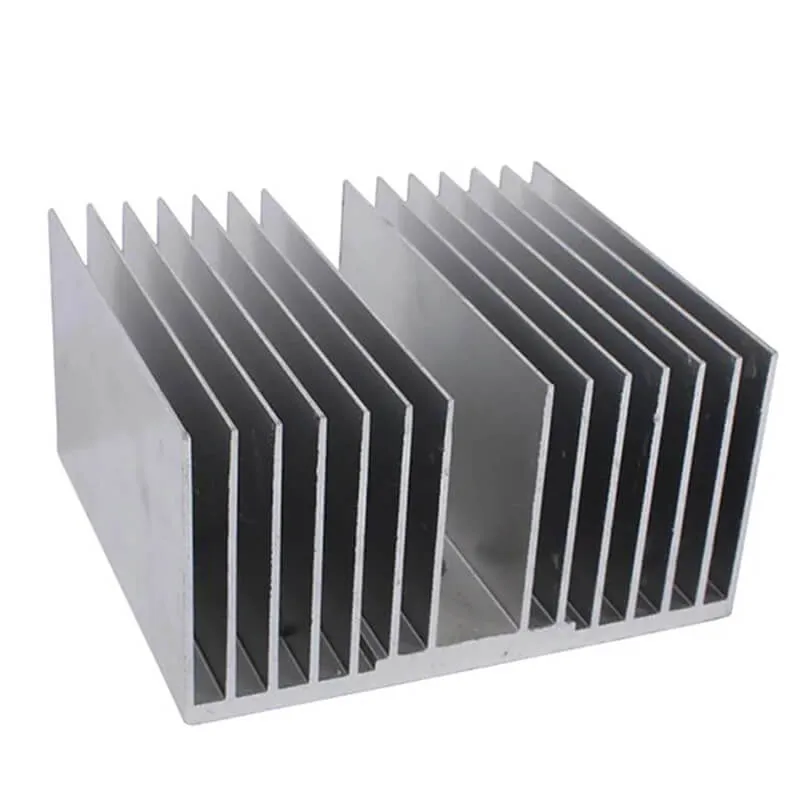

High-Quality Extruded Aluminium Profiles

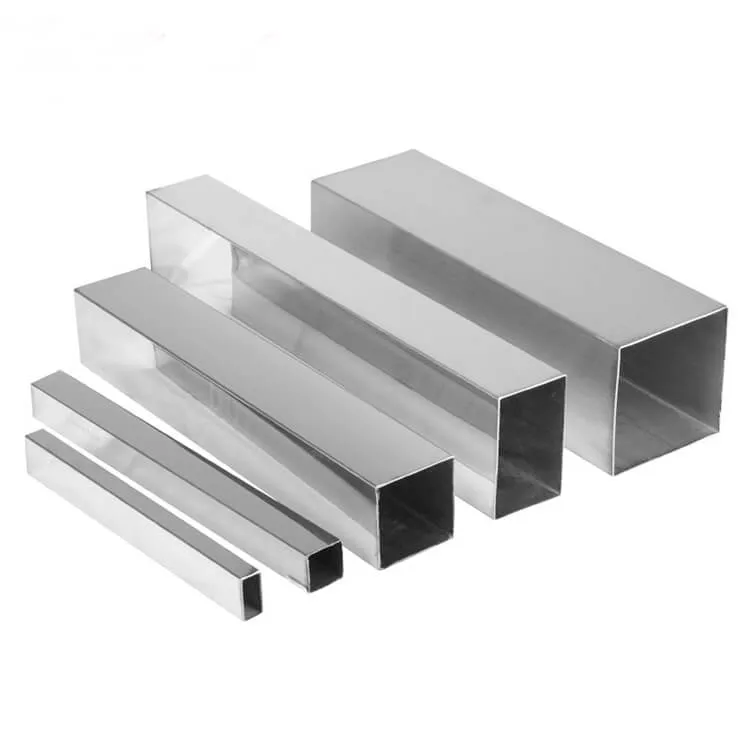

Durable Aluminum Tubing

More Than 10 Years of Experience in the Aluminum Industry

Advanced Extrusion Presses Line with 35 Units

Boost Your Business with a Minimum Order Quantity (MOQ) of 500KG Only

Comprehensive Loading Report Support Provided for Every Shipment

Our Aluminum Extrusions are Guaranteed to be Made from 100% Pure A00 Aluminum Ingot

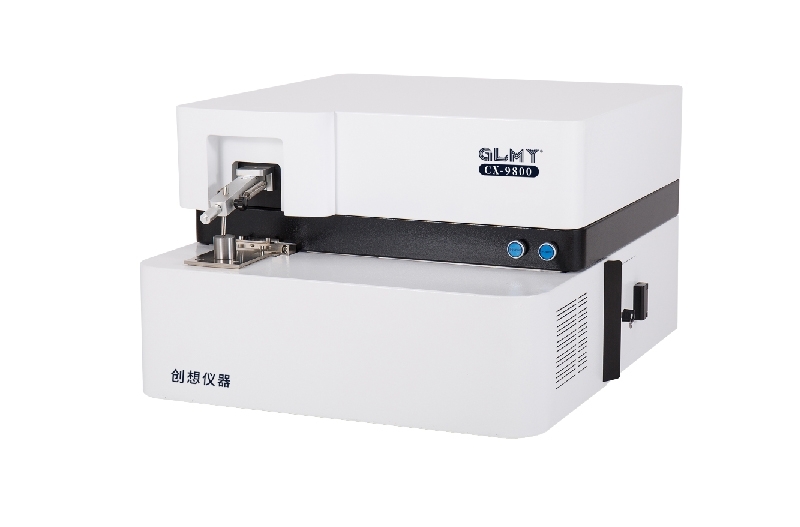

Sourcify Provides In-House Mechanical Testing and Certificate Reports for Every Shipment

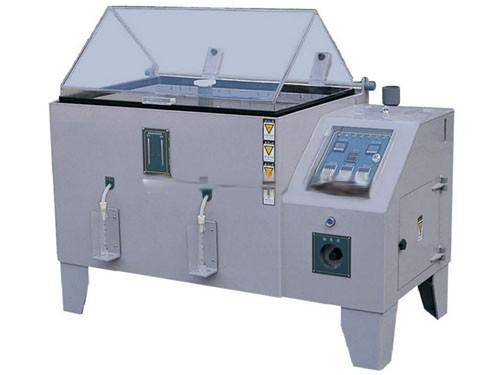

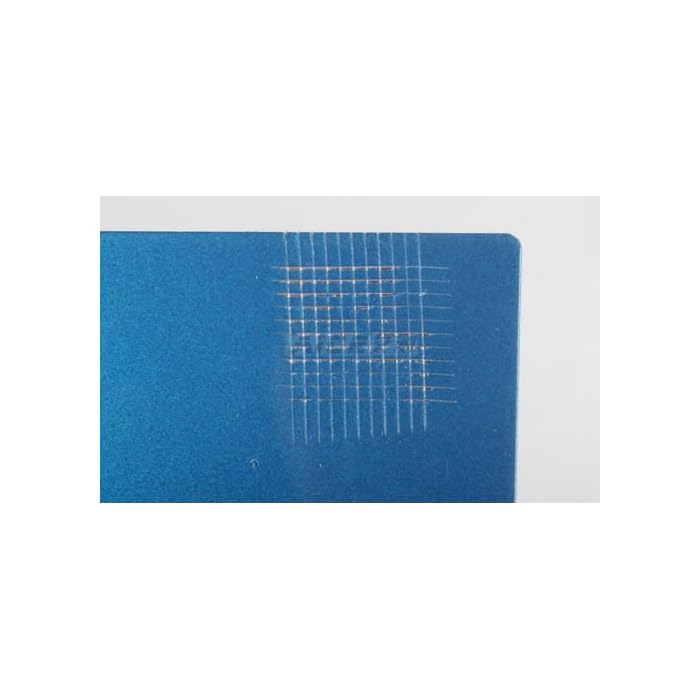

Our Quality Control Team Randomly Selects Coating Surfaces for Salt Spray Testing to Ensure Quality

Also Referred to as Paint Adhesion Testing, We Conduct 100% Inspection Throughout the Manufacturing Process

Sourcify Boasts a Team of Over 30 Experienced Engineers in the Aluminum Industry. We Offer Custom Aluminum Extrusions and Product Design Services, Even if You Only Have an Idea.

As an ISO9001-2001 Certified Company, Sourcify Operates 35 Extrusion Lines, 5 Anodized Lines, 5 Sprayed Production Lines, and 1 PVDF Production Line.

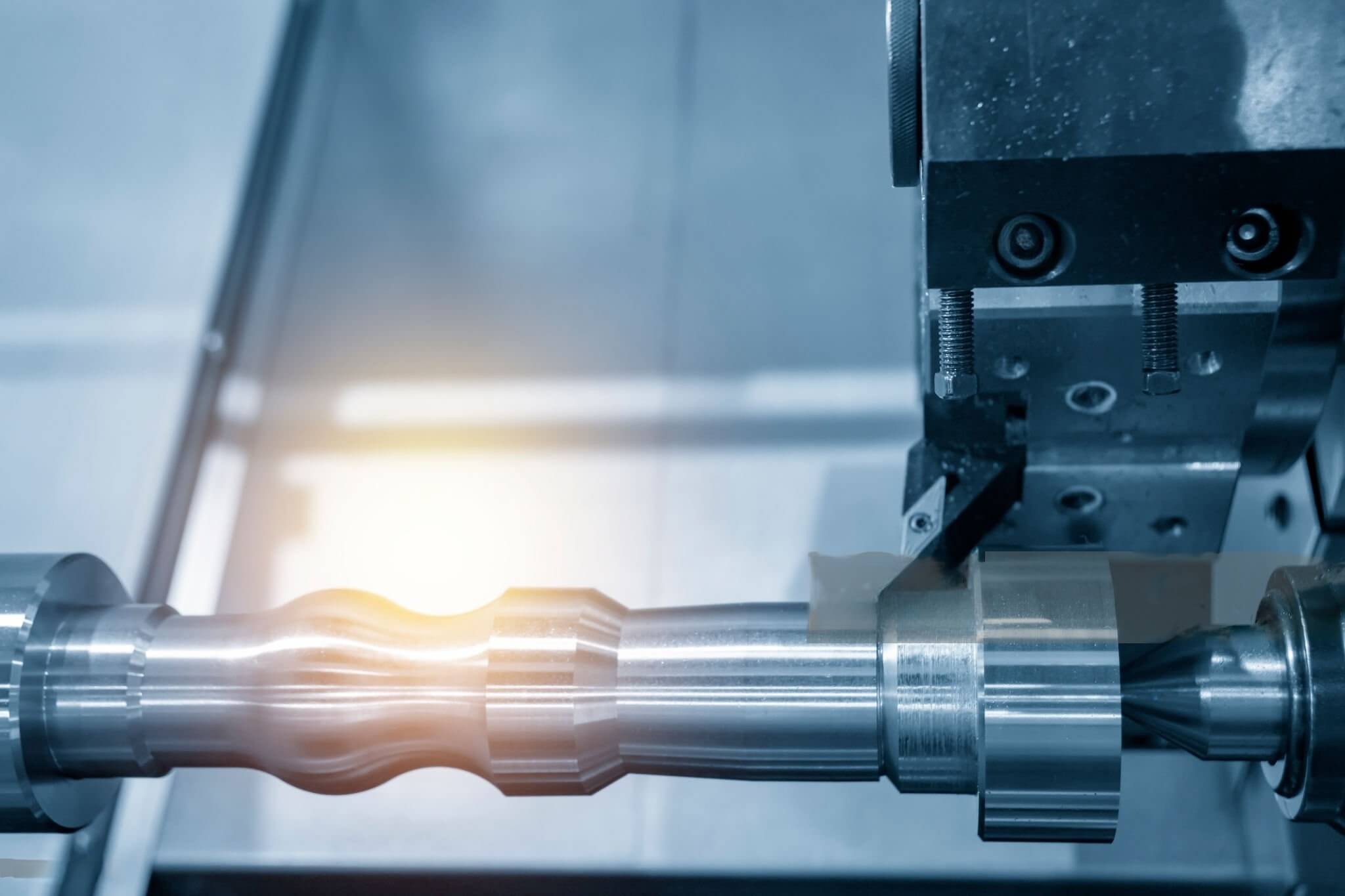

Sourcify Offers Integrated Services Including Research, Design, Extrusion, and Advanced Machining Such as Cutting, CNC Machining, Bending, Stamping, Welding, and More.

Sourcify: Your Trusted

Sourcify’s Technical Staff is Available 24/7 for Immediate Support and Expert Advice on Your Products, Sharing Engineering Knowledge. We’re Here to Support Your Business, Regardless of Whether You Place an Order.

Harley Zhu.

Company Director

We Operate Two Shifts Without Interruption to Ensure Timely Delivery of All Orders and Goods.

Tom Lee.

Factory Buyer

Sourcify Accepts a Variety of Aluminum Extrusion Drawing Files, Including DWG, DXF, PDF, and IGS. If You Have a Rough Sketch, Our Engineers Can Assist in Creating Drawings at No Cost.

The time required to create tooling for a bulk order can vary depending on the complexity of the design and our current production schedule. Generally, it takes approximately [insert estimated time] to complete tooling for bulk orders. Please contact our team for a more accurate estimate based on your specific requirements.

Yes, we offer low MOQ (Minimum Order Quantity) options for custom aluminum extrusions. Our flexibility in MOQ allows us to cater to a wide range of project sizes and requirements. Please contact our sales team to discuss your specific needs, and we will work with you to determine the most suitable MOQ for your project.

Yes, we can supply custom aluminum fabrication services to meet your specific needs and requirements. Our experienced team is ready to work with you to create tailored aluminum products based on your design and specifications. Please feel free to share your project details with us, and we will be happy to assist you in achieving your customization goals.

To work with Sourcify for custom aluminum extrusion, you can follow these steps:

Initial Consultation: Reach out to our team with your project requirements. You can contact us through our website, email, or phone.

Project Discussion: We will schedule a consultation to discuss your specific needs, including design, dimensions, quantity, and any other relevant details.

Design and Quotation: Our engineering team will work on creating or refining the design based on your requirements. We will then provide you with a detailed quotation that includes pricing, lead times, and MOQ if applicable.

Prototype and Approval: Upon your approval of the quotation, we will proceed to create a prototype or sample for your review and approval. Any necessary adjustments will be made at this stage.

Production: Once the prototype is approved, we will initiate the production process, which includes tooling, extrusion, fabrication, and finishing.

Quality Control: Our quality control team ensures that all products meet the specified quality standards at every stage of production.

Packaging and Shipping: We will carefully package the custom aluminum extrusions and arrange for shipping to your designated location.

Post-Sale Support: Sourcify is committed to providing support even after the sale, should you have any questions or concerns.

By following these steps, you can collaborate with Sourcify to achieve your custom aluminum extrusion needs efficiently and effectively.

We are capable of extruding a wide range of aluminum alloy numbers, including but not limited to:

If you have a specific alloy in mind or if you need guidance on selecting the right alloy for your project, please let us know, and our team will assist you in choosing the most suitable option.

We offer a variety of surface treatment options for our aluminum extrusion products, including:

Anodizing: This process enhances corrosion resistance and provides a durable, decorative finish. It is available in various colors.

Powder Coating: Powder coating offers a wide range of color options, excellent durability, and a uniform finish.

Electrophoretic Coating (E-Coating): E-coating provides corrosion resistance and a uniform finish, often used for automotive and industrial applications.

Polishing: We can provide polished finishes to achieve a reflective, shiny surface.

Brushing: Brushed finishes create a textured appearance and are often used for architectural and decorative purposes.

Wood Grain Finish: We offer wood grain finishes to mimic the look of wood on aluminum profiles.

Custom Finishes: If you have specific surface treatment requirements or custom finishes in mind, please let us know, and we can work to accommodate your needs.

Our team will assist you in selecting the most suitable surface treatment for your application, ensuring that it meets your functional and aesthetic requirements.

Sourcify accepts various payment terms to accommodate our clients' preferences and needs. Our accepted payment terms include:

T/T (Telegraphic Transfer): This is a commonly used payment method involving a bank transfer. It typically requires an upfront deposit and a balance payment before shipment.

L/C (Letter of Credit): L/C is a secure method of payment where a bank guarantees the payment on behalf of the buyer. It provides assurance to both parties in the transaction.

PayPal: We also accept PayPal payments for convenience and ease of use, especially for smaller transactions.

Western Union: Western Union transfers are accepted for quick and efficient payments.

Other Payment Terms: Depending on the nature of your project and agreement, we may consider other payment terms that are mutually beneficial.

Our goal is to provide flexibility in payment options to ensure a smooth and secure transaction process. Feel free to discuss your preferred payment terms with our team, and we will work together to find the most suitable arrangement for your project.

We take great care in packaging our aluminum extrusion profiles to ensure they arrive safely and in optimal condition. Our packaging methods typically include:

Protective Film: We apply a protective film to the surface of the profiles to prevent scratches or damage during handling and transit.

Bundling: Profiles are securely bundled together to minimize movement and potential damage during transportation.

Foam Inserts: Depending on the profile shape and size, we may use foam inserts to cushion and protect critical areas.

Custom Packaging: For unique or fragile profiles, we design custom packaging solutions to provide additional protection.

Wooden Crates or Pallets: Aluminum extrusion profiles are often placed in wooden crates or on pallets for added stability and ease of handling.

Labeling: Each package is clearly labeled with essential information, including product details, quantity, and handling instructions.

Our packaging methods are tailored to the specific requirements of your order and the nature of the aluminum extrusion profiles. We prioritize the safe and secure delivery of your products to their destination.

We offer a wide range of standard structural aluminum extrusion shapes to meet various industry and application requirements. Some of the common shapes we have available include:

These standard shapes are versatile and widely used in industries such as construction, manufacturing, automotive, and more. If you have specific shape requirements or need assistance in selecting the right profile for your project, please feel free to reach out to our team, and we will be happy to help you find the suitable structural aluminum extrusion shape for your needs.