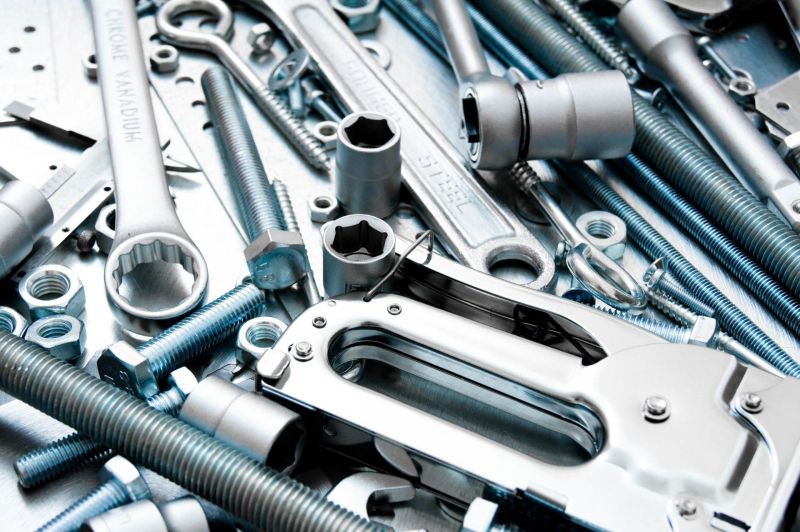

Mould Design

CUSTOM MOLD MAKING

Manufacturing high-quality plastic components and assemblies with precision injection molding.

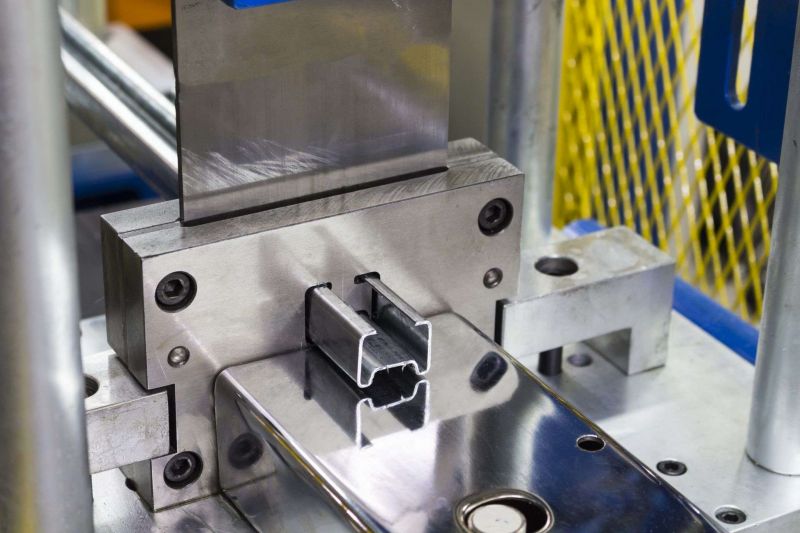

Sourcify Molding Co., Ltd. is a renowned plastic injection molding company based in the bustling city of Shenzhen in China. With over 10 years of experience and a highly skilled team of experts, we excel in offering top-quality services that include not only mold design and plastic injection molding but also custom injection molding.

Our pre-sales team comprises seasoned plastic injection mold engineers who can communicate seamlessly and without any hurdles. Get in touch with us today to receive a quote and experience unmatched excellence!

At China Molding Co., Limited, we specialize in plastic injection molding services and manufacturing various plastic molds for automotive, home appliances, electronics, and general industrial OEM applications. Our factory spans over 2000 square meters and is conveniently located near transportation access.

With over 100 employees and capital assets exceeding 8 million RMB, we have the capacity to produce 40-50 plastic injection molds per month. Our mission is to be a trustworthy, creative mold maker and plastic injection mold manufacturer. Our top-level management is heavily involved in a modern management system, and our goal is to achieve zero defects.

We utilize continuous improvement and innovation to be your preferred supplier for your company’s needs.

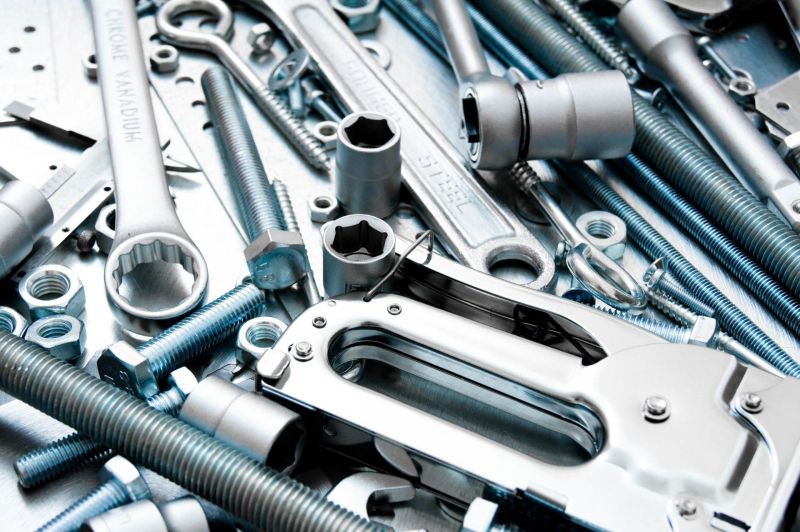

Unlike many large mold manufacturers in China that cannot offer factory direct prices, our medium-sized injection molding company is able to provide lower costs due to our scale. Our smaller size results in reduced administrative expenses compared to larger factories, allowing us to pass these savings onto our customers. We are certified with ISO9001-2008, ensuring that our quality is on par with bigger manufacturers. Despite the fact that molds in China are generally less expensive than those in the USA or Europe, the cost of plastic injection molding can be higher due to the elevated prices of resin in China, which can be 50%-100% higher. However, for custom plastic components quantities ranging from 1,000 to 50,000 pieces, China offers significant cost advantages.

As a medium-sized provider of custom injection mold and plastic injection molding services, our size not only allows us to offer competitive pricing but also reduces our overhead costs compared to larger factories. Holding an ISO9001-2008 certification, we guarantee quality that rivals that of larger manufacturers. Our in-house capabilities include printing, painting components, and assembly, offering a comprehensive solution that can result in substantial savings for our clients.

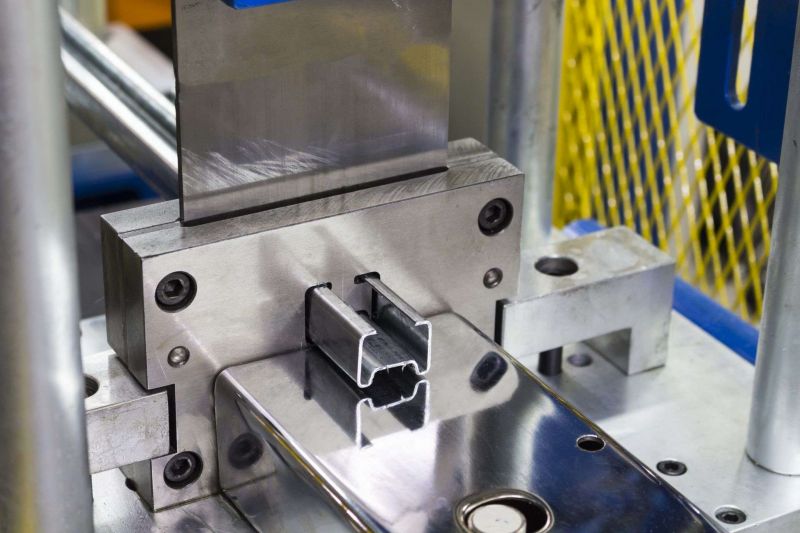

In contrast to many companies in China that employ sales personnel with only basic English skills and no mold engineering experience, our sales managers possess extensive engineering expertise. Typically, these sales representatives merely relay customer communications to mold makers and occasionally send holiday greetings, while earning a commission (3-5% of the mold cost, which is usually included in their quotes). At our company, sales managers assigned to your project will fulfill both sales and project management roles, ensuring a high level of service continuity and efficient communication throughout the entire project.

I’m extremely satisfied with your product! Your team did an amazing job and deserves recognition. Working with Creacy was a pleasure; he went above and beyond expectations. We look forward to collaborating with him again, and I’ll gladly recommend him and your company to any potential clients asking for references.

Injection molding costs depend on material, mold design, cycle time, and overhead. Careful consideration is key to cost optimization and successful manufacturing.

What is ABS Injection Molding Material? ABS is an opaque thermoplastic polymer commonly used in injection molding. Because it is amorphous, it does not have a true melting point.

Plastic injection molding outperforms other manufacturing methods, offering versatile advantages for producing high-quality, complex plastic parts efficiently and cost-effectively.